TELESCOPIC RAIL

Light steel draw slides are frequently used for desk draws, filing cabinets or other light duty applications. As an alternative paired linear bearings can be used to support a moment load, usually requiring an oversized bearing system. When your application requires precision, high loads and/or continuous movement then Rollon Telescopic Rails give the designer a compact, high load and smooth running solution.

- Door movements

- Telescopic press arms

- Product extraction

- Retreval systems

- Any application where extraction, expansion, movement or extension is required.

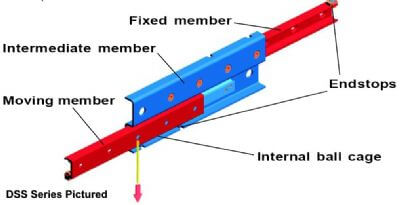

Rollon Telescopic rails are constructed from cold-drawn carbon steel with most types featuring hardened raceways. The rugged construction ensures rigidity and minimal deflections even when carrying rated loads at full extension. Deflection in lighter slides causes the load to fall to one end and also results in variation in the force required to move the load. Rollon Telescopic rails quality construction provides consistent movement even when vibrations, impacts or shock loads are present. Rollon Telescopics are superior to a conventional draw slide, carrying higher loads with a longer service life in extreme applications.

DS S shaped intermediate member with single or double stroke versions and slim cross section with space saving benefits.

DE I shaped intermediate member featuring very rigid movement and high radial load capacity.

DBN Square shaped intermediate member of compact dimensions with high radial and axial load capacity.

DMS Structural I beam ultra high load type.

ASN Single slide with induction hardened raceways and semi-telescopic movement.

LTF44 S shaped intermediate member with non-hardened raceways and compact size, with high load carrying in low frequency applications.

Key benefits of Rollon Telescopic rail.

- Smooth, accurate movement for precision motion and high quality machine feel.

- Corrosion protection options with nickel coated rails and chrome plated or SS ball bearings for chemical, wet areas or caustic wash down environments.

- Strokes of up to 2m and loads of 900kg for high load or long stroke applications.

- Low friction for reduced drive motor requirements or user effort. You can save money on drive components or provide a higher quality feel to your machines.

- Long working life for reduced maintenance, saving downtime and production.

- Precision construction allows speeds of up to 0.8m/s for increased machine cycle times.

- Temperatures up to 130degC for a wide variety of environments, and up to 170degC with high temperature lubrication.

you can find more details on Rollon Telescopic rail including drawing files from this page on our website. Even better call us with your application as we appreciate being able to work with you on your enquiry.

Contact Us

Contact Us