PROVEN AND DURABLE LINEAR DRIVE

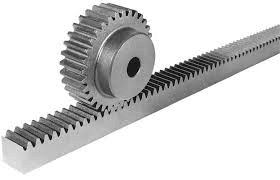

Rack and pinion drives have been around for centuries and can often be overlooked in linear drive situations. Modern manufacturing methods can produce highly accurate drives suitable for a wide range of industrial applications.

A key benefit of a rack and pinion drive is durability. The wide contact area of the tooth face makes them less sensitive to particulate contamination than other types of drives. This makes them are highly suitable for agricultural, cutting or dirty applications that would otherwise require extensive contamination protection.

Long travel lengths are an area where rack and pinion really comes into its own. By having the pinion traveling with the payload the rack can be fastened along the length providing a highly rigid drive. This is also a safer arrangement as the only moving part is the pinion situated at the payload. Most factory racks have the lengths machined ready for butt joining. Tooth pitch consistency at the joins can be improved by simply meshing the teeth of a short piece of rack across the join when fastening the rack down. For shorter travel lengths the reverse arrangement with the motor fixed and the rack moving can reduce inertia loads and simplify cabling.

All rack and pinion drives require some clearance to avoid excessive wear. For a precision machined rack and pinion accurate mounting of the gear and rack PCDs will give the optimum balance of low backlash and long service life. In practice lower backlash can be achieved by preloading the pinion into the rack at the expensive of increased wear. Most modern control systems also have built in backlash compensation which can be used to avoid potential positioning errors in high cycling applications.

We have precision rack and pinion drives ex stock in metric module 1 to 4 with pitch precision approximately 0.06/300mm. Other modules. higher precision, ground, helical or stainless racks can also be supplied on indent.

Linear motion has NZ’s most experience team of linear specialist and are happy to assist in specifying suitable linear drive systems.

More details on rack and pinions can be found on this page of our website. Or give us call to discuss any projects you may be working on.

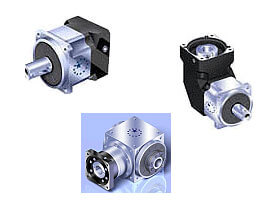

Precision Gearboxes

Due to the high lead of a pinion drive a precision gear box is often required. Precision gear heads are typically of planetary design for compact size and ability to run high input speeds. High end models will have precision ground helical teeth for ultra low backlash and compact size.

We can supply a wide range of inline, right angle, helical or spur gear drives to suit rack and pinion applications.

More details on gear boxes can be found on this page of our website. Or give us call to discuss any projects you may be working on.

Contact Us

Contact Us