ORDERING LINEAR RAIL

Linear rail comes in stock lengths and IAS will happily cut to your required size for a minimal charge. Most rail systems can be jointed for extra long applications.

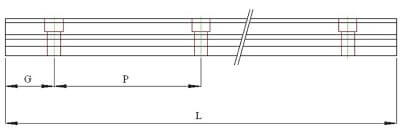

When ordering a length of linear rail the pitch size of the rail mounts needs to be considered. If a length of rail is requested without further details IAS will centralise the holes along the span required. Alternatively you can specify the “G” distance from one end of the rail to the centre of the first hole.

Example ordering code

TEX30-1200 (G=15)

Stainless steel Rollon X-rail 1200mm long with the first hole 15mm from one end.

Selection considerations

Here are some generalised things to consider when designing and selecting a linear system. This is not an exhaustive list and final selection depends on your application.

- Stroke/length of travel

- Speed

- Load and weight

- What sort of preload is required

- Support points and number of carriages

- Orientation vertical or horizontal

- Cantilever loads and overhanging considerations

- Wash down and corrosion resistance

- Chemical environment considerations

- Food contamination issues

- Service life

- Amount of years required. Excessive requirement will significantly increase size and costs

- Frequency

- How often the motion is required

- Driving mechanism

- Belts, trapezoidal, actuator, ball screw. AC, DC, stepper or servo motors

- Safety factor

- How much margin should be built in?

- What are the consequences of failure

- Physical human safety

- Production requirements

- Availability of parts

Contact Us

Contact Us