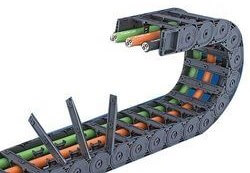

CABLE CHAIN

Cable management is an import part of machine design but often overlooked. Properly controlling the movement of cables and hoses is critical to the reliability of high cycling applications. Hoses and cables left free are exposed to rubbing, twisting or pinching and can just simply get in the way or tangled in parts of the mechanism. Cables that are forced into a bending radius less than their natural or recommended radius will also suffer from fracturing of the insulation and conductors due to accelerated fatigue. This will manifest as erratic running, failures and costly downtime. The problem is best solved by the use of the articulated support systems known as cable chain, cable carrier or energy chain.

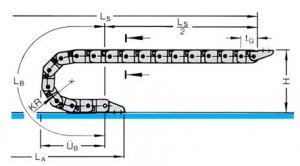

Cable chain has a segmented construction with an articulated pin connection between adjacent segments. Each segment has a lug or stopper that restricts the range of articulation and determines the radius of bending. Segments are connected together to make up a chain of any length. One end of the chain is connected to a fixed point and the other to a moving point on the mechanism. The distance between the fixed and moving points at one end of the stroke is half the overall travel length as the assembly can articulate over itself and the moving point can travel the same distance to the other side of the fixed point.

The easiest types to use have opening cross bars. This allows the assembled cable chain to be laid down flat, the bars opened and the cable laid directly into cavity. A range of internal separating plates are available or cables and hoses can be simply cable tied to cross bars if extra support or security is required. There are a number of variables in sizing a cable chain but the primary constraint is the required cables should have around 30% free space inside the cross section of the cable chain.

We stock Shinflex open cable chain to suit a wide range of linear applications. Shinflex of Korea make an excellent quality cable chain at very reasonable prices. All our stock types have opening bars for easy cable or hose installation and usually have the smallest bend radius for space saving.

Their full range includes open and closed plastic cable chains through to high load metal framed systems. Shinflex can also supply complete systems with dividing stays and support troughs.

Our customers have had outstanding results with Rollon Compact Rail in a wide variety of applications including robotics, packaging, X-Y tables and materials handling.

Additional information can be found here along with two and three dimensional drawing files, or the Compact Rail catalogue. Feel free to call fax or email IAS with your application requirements.

Contact Us

Contact Us